Impact-Resistant Aluminum roof tiles: Durable, Lightweight, and Long-Lasting Roofing Solutions

In modern construction, roofing materials must withstand extreme weather conditions, hailstorms, and physical impact while maintaining aesthetic appeal and energy efficiency. Impact-resistant aluminum roof tiles are engineered to meet these challenges, offering high mechanical strength, lightweight design, and corrosion resistance.

These tiles are ideal for residential, commercial, and industrial buildings, providing long-lasting protection, low maintenance, and environmental sustainability. Their reinforced aluminum alloy construction and advanced coatings ensure that roofs remain intact and safe, even under severe conditions.

Impact-Resistant Aluminum Alloy: Withstands hail, falling debris, and strong winds.

Lightweight Design: Reduces roof load, simplifying installation and structural requirements.

Corrosion Resistance: Durable against rain, humidity, and environmental pollutants.

Thermal Insulation: Enhances energy efficiency and indoor comfort.

Fire Resistance: Meets Class B1/B2 fire safety standards.

Easy Installation: Interlocking design allows fast and secure assembly.

Low Maintenance: Requires minimal inspection and cleaning.

| Specification | Details |

|---|---|

| Base Material | Aluminum Alloy 5052 / 6061 |

| Tile Thickness | 0.6–1.5 mm |

| Tile Width | 200–350 mm |

| Tile Length | 800–2500 mm |

| Thermal Conductivity | ≤ 0.025 W/(m·K) |

| Fire Resistance | Class B1/B2 |

| Impact Resistance | Hail resistance ≥ 20 mm diameter at 30 m/s |

| Coating | PVDF, PE, or Nano self-cleaning |

| Weight | 3–6 kg/m² |

| Lifespan | 25–30 years |

| Applications | Residential, commercial, industrial |

Customer reviews highlight the durability, aesthetic versatility, and low maintenance requirements of impact-resistant aluminum roof tiles.

Residential Users: Appreciate easy installation, reduced roof weight, and aesthetic appeal.

Commercial Clients: Value long-term durability, energy savings, and fire resistance.

Industrial Applications: Highlight resistance to physical damage, corrosion, and extreme weather.

| Customer Type | Feedback |

|---|---|

| Homeowner | "Our new aluminum roof has withstood hailstorms without any dents. It looks great and is very low-maintenance." |

| Factory Owner | "The lightweight tiles reduced our roof load, and their impact resistance protects machinery inside from structural damage." |

| Architect | "These tiles are versatile in design and color, making them ideal for sustainable modern projects." |

Inspect roof structure for stability and slope compliance.

Confirm tile quality, dimensions, and coating integrity.

Prepare tools, fasteners, sealants, and safety equipment.

| Step | Instruction |

|---|---|

| 1 | Begin at the bottom edge of the roof, moving upwards. |

| 2 | Align tiles for proper interlocking and overlap. |

| 3 | Secure each tile with stainless steel screws or clips. |

| 4 | Apply sealant at joints and edges for waterproofing. |

| 5 | Install ridge caps, flashing, and ventilation components. |

| 6 | Inspect final installation for alignment, fastening, and surface integrity. |

Wear helmets, gloves, and anti-slip footwear.

Use safety harnesses on steep or elevated roofs.

Avoid walking directly on tiles; use planks or protective boards.

Handle tiles carefully to prevent scratches or dents.

Proper maintenance ensures long-term performance and durability.

Visual Inspection: Look for loose tiles, corrosion, scratches, or dents every 6 months.

Cleaning: Use mild detergent and water; avoid abrasive tools.

Debris Removal: Clear leaves, moss, and dirt to prevent water retention.

Sealant Inspection: Check and reapply sealant as necessary.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Every 6 months |

| Cleaning | Twice per year |

| Coating Check | Every 5 years |

| Fastener Tightening | Every 12 months |

| Sealant Renewal | Every 5 years |

Understanding possible faults allows for prompt repairs and prolonged lifespan.

| Fault | Possible Cause | Solution |

|---|---|---|

| Dents after hail | Excessive hail size or velocity | Inspect, replace damaged tiles |

| Corrosion spots | Scratches in coating or exposure to chemicals | Clean affected area, apply touch-up coating |

| Loose tiles | Improper fastening or thermal expansion | Retighten fasteners, use expansion allowances |

| Water leakage | Incorrect overlap or sealant failure | Reseal joints, check alignment |

| Color fading | UV exposure over time | Apply protective coating, ensure UV-resistant paint |

Surface Scratches: Apply touch-up paint or coating.

Loose Fasteners: Tighten or replace with stainless steel screws.

Small Dents: Use rubber mallet or professional restoration techniques.

Tile Replacement: Remove damaged tile, align new tile, secure with clips or screws, reseal edges.

Structural Damage: Inspect roof structure, repair underlying beams or decking, then reinstall tiles.

For extensive hail damage, fire exposure, or structural faults, contact certified roofing specialists.

Ensure insurance coverage and warranty compliance when performing major repairs.

Recyclable Aluminum Alloy: Tiles are 100% recyclable, contributing to sustainable building practices.

Eco-Friendly Coatings: PVDF, PE, or nano coatings comply with RoHS and REACH standards.

Energy Efficiency: Lightweight tiles improve thermal insulation, reducing energy consumption.

Reduced Carbon Footprint: Lightweight design lowers transportation and installation emissions.

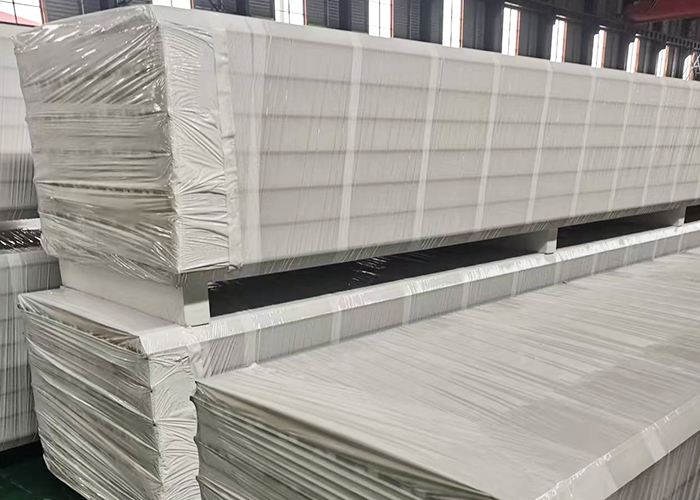

Stack tiles horizontally with protective separators.

Use pallets, crates, or reinforced packaging to prevent movement.

Apply waterproof wrap to avoid moisture damage.

Clearly label tile type, dimensions, and handling instructions.

Avoid dropping or impact during loading/unloading.

Protect from direct sunlight and moisture exposure.

Secure tiles during transit to prevent bending or coating scratches.

| Feature | Impact-Resistant Aluminum Tiles | Clay Tiles | Asphalt Shingles |

|---|---|---|---|

| Weight | 3–6 kg/m² | 30–40 kg/m² | 10–15 kg/m² |

| Impact Resistance | High | Low | Medium |

| Corrosion Resistance | Excellent | Low | Medium |

| Thermal Insulation | High | Medium | Low |

| Maintenance | Low | Medium | High |

| Installation Speed | Fast | Slow | Moderate |

| Lifespan | 25–30 years | 15–20 years | 15–25 years |

| Fire Resistance | Class B1/B2 | Low | Class C |

Impact-resistant aluminum roof tiles provide exceptional protection, longevity, and energy efficiency. Designed for residential, commercial, and industrial applications, they withstand hail, extreme weather, and physical stress while remaining lightweight and easy to install.

By following installation guidelines, maintenance schedules, and repair procedures, property owners can maximize the lifespan and performance of their aluminum roofing system. These tiles represent a sustainable, durable, and cost-effective roofing solution for modern construction projects.

Contact Person: Wang Ye

Tel: +86 158 33457666

Email: 944713874@qq.com

Address: South side of Yuxin Highway, Dongxian Village, Yahongqiao Town, Yutian County, Tangshan City, Hebei Province

Copyright © 2025 Tangshan Juze Technology Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.